|

The design of the aircraft incorporated a blended wing and body configuration. The wings were a cantilever, low-wing, fail-safe, blended wing-body structure, with variable geometry on outer panels. Principal materials used in construction of the B-1 were aluminum alloys and titanium-the latter being used primarily in the wing carry-through structure, engine nacelles, and aft fuselage. The balance of the airframe was made up of steel and a number of non-metallic materials. The bomber was powered by four General Electric (GE) YF101-GE-100 afterburning turbofan engines. They were mounted in pairs beneath the fixed center section of the wing close to the center of gravity, to provide the greatest stability in low-altitude turbulent conditions.

The original B-1 was designed to operate near-sonic speeds at treetop heights at supersonic speeds at high altitude. The operational concept called for the bomber to be able to penetrate well-defended enemy airspace to deliver nuclear or conventional bombs. The B-1 had a radar signature only 5% that of the B-52, carried nearly twice the payload, and could make use of shorter runways. B-1 pilots came to call their airplane "The Bone" (short for "B-One.")

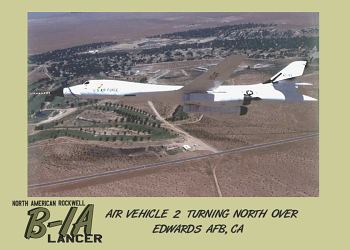

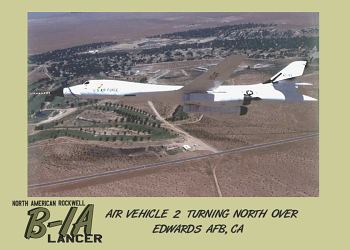

The B-1 prototypes were assembled in the Rockwell facility at Air Force Plant 42 in Palmdale, California, beginning in late 1972. The second prototype B-1A (74-0159), known as Air Vehicle 2 (AV-2), served as the structural test aircraft during the flight test program. AV-2 was rolled out from the production facility on 11 May 1976 and made its first flight on 14 June 1976, piloted by Tommie D. "Doug" Benefield.

In June 1977, the B-1 production program was cancelled in its entirety following the election of President Jimmy Carter. However, research and development flying by the four prototypes was allowed to continue at Edwards AFB, with the ability of the aircraft to fly at Mach 2.2 demonstrated in October 1978. This flight program came to an end on 29 April 1981 with a final flight by AV-4, by which time the combined total of test hours flown by the prototypes had reached 1,895 hours. AV-2 Made 60 flights in the course of the B-1A test program prior to its cancellation.

AV-2 was later modified to support the B-1B test program in March 1983. Modifications included new weapons bay doors, changes to some bulkheads, and the addition of a B-1B flight control system. The modified AV-2 made its first flight on 23 March 1983. During the B-1B test program, AV-2 was used to conduct stability, control, flutter, and weapon separation tests. The aircraft completed initial separation tests with the Short Range Attack Missile (SRAM), Mk.82 conventional high explosive bomb, and B61 and B83 nuclear weapon shapes. AV-2 was scheduled to be modified for Air Launched Cruise Missile (ALCM) testing in mid-1985. The aircraft logged 66 flights during the B-1B test program. AV-2 logged a total of 543 flight hours during its service life.